Humid Areas

Adhesion of material to components

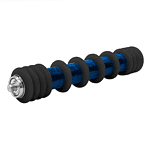

In ore processing, there are wet areas or processes involving acids, water and other liquids that cause the material to adhere to the surface of the roller. The adhering material forms a layer of crust or shavings that hinders the movement of the conveyor belt, resulting in misalignment, increased energy consumption and a substantial reduction in the service life of the roller.

At ULMA Conveyors Components we have developed different types of coatings with special shapes that reduce the adherence of the material on the belt and increase the service life of the roller by 50%.

PERFORMANCE

Premium quality product range to optimize performance under normal conditions.

The Performance line offers a wide selection of rollers made with high-quality components under a rigorous manufacturing process.

In addition, the range includes a sealing system designed and patented by ULMA, which guarantees effective sealing and optimum protection for the bearings.

ENDURANCE

Range of products developed to guarantee maximum durability in extreme conditions.

The Endurance line offers a wide selection of rollers developed with high-quality components and special materials and coatings. All this is to guarantee optimum performance in the most demanding cases.

The sealing package, developed and patented by ULMA, ensures effective sealing and optimum protection, guaranteeing performance and durability.