ULMA roller sealing system in Potash Works 2026:

4 lines of defense to keep the roller turning.

The ULMA roller sealing system is featured in the latest issue of Potash Works 2026. In this publication, we defend the core purpose of a roller: to turn.

Rollers, on their own, are not particularly mysterious. After all, they are simply cylinders that must rotate on a shaft. They are not cars. They are not airplanes. And we certainly are not asking them to do what a smartphone does.

Put that way, it doesn’t sound too difficult for them to do their job. The fine print is that we want them to keep turning under extreme conditions — when the environment tries to stop them from the very first minute.

In potash mining, something especially complex happens: rollers must face different extreme conditions, all at the same time.

- Underground: fine, persistent, highly abrasive dust that tries to get in everywhere.

- On the surface: very cold conditions while handling material at extremely high temperatures.

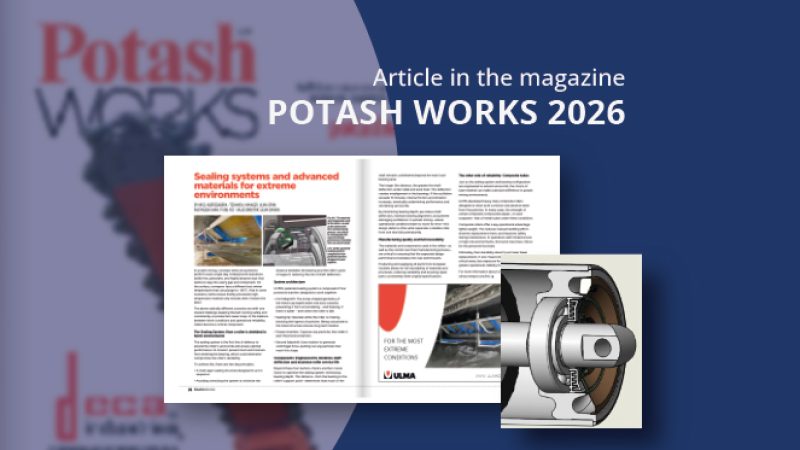

When this happens, it is essential to protect both the exterior and the interior of the roller. That is why the roller sealing system is so critical. A barrier — or in the case of ULMA rollers, four barriers working in sequence — protects the bearing so that, in the end, the roller can do the only thing it is meant to do: turn.

How the 4 barriers work.

- First labyrinth: pushes water outward.

- Contact lip: blocks particles while rotating.

- Grease chamber: captures anything that manages to get through.

- Second labyrinth: expels dirt outward through the roller’s own rotation.

Take a look at the full article to discover all the details!

flipbooks.delcommunications.com/PW2026