Dusty Environments

Facilities with an accumulation of fine dust

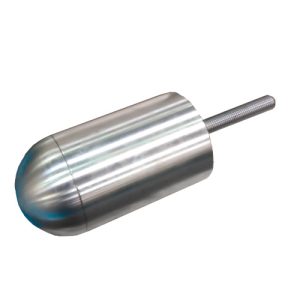

Very fine and abrasive dust, such as that generated by phosphates, severely affects the heart of the roller: the bearing.

At ULMA Conveyor Components we have developed and patented a sealing system that protects the bearing of our rollers and pulleys in extremely dusty and critical conditions.

In addition, our laboratory has specialized equipment for testing and trials with fine and abrasive powders.

PERFORMANCE

Premium quality product range to optimize performance under normal conditions.

The Performance line offers a wide selection of rollers made with high-quality components under a rigorous manufacturing process.

In addition, the range includes a sealing system designed and patented by ULMA, which guarantees effective sealing and optimum protection for the bearings.

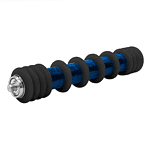

ENDURANCE

Range of products developed to guarantee maximum durability in extreme conditions.

The Endurance line offers a wide selection of rollers developed with high-quality components and special materials and coatings. All this is to guarantee optimum performance in the most demanding cases.

The sealing package, developed and patented by ULMA, ensures effective sealing and optimum protection, guaranteeing performance and durability.