The Bulk Handling Technology has already started its transformation to the Industry 4.0. Having some of the harshest working and environmental conditions of the industry, the possibility of remote analysis and maintenance of the components seems a perfect target to focus on. The most important and expensive tools have been adapted to the digital era during last years, from remotely controlled haul trucks to monitored conveyor belts. However, these big parts of the installations rely in smaller parts that have been left aside for a while, mainly due to the difficulty to adapt them to IoT (Internet of Things) The paradigmatic example is the lack of monitored rollers whereas all the other components of the conveyor belt installations (the belt itself, motors, drums etc.) were monitored some time ago. The main problem is that a failure of a single roller can cause the stop of the whole conveyor, due to the possible damages to the belt, thus the implementation of an integral monitoring system of all the components of the conveyor is a must.

The digitalization of rollers has very unique difficulties in addition to the usual IoT implementation challenges. It’s remarkable the high number of rollers in some installations (more than several thousands in a common overland), the demanding electromagnetic environment (metallic structures, metallic particles suspended in the atmosphere etc.) that interfere in the communications or the continuous contact with aggressive agents like iron ore or potash.

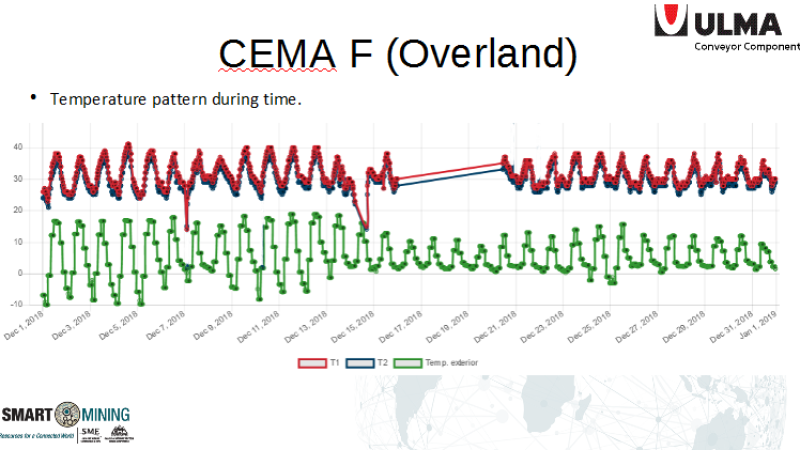

The R&D Department of ULMA Conveyor Components, has been working since early 2012 on the development of Monitored Rollers facing all the problems until its final installation in very different demanding conveyors, from the Australian extreme heat to the freezing cold Norway. All the tests done under actual working conditions, in real installations, have given a valuable knowledge in the identification of problems, their solution and the final advantages of a roller monitoring system.

ULMA Conveyor Components is proud to introduce its analysis of the current situation of Monitored Rollers Technology, how has been possible to reach to a real working solution and which are the advantages that this technology is already offering.