CONVEYOR SOLUTIONS

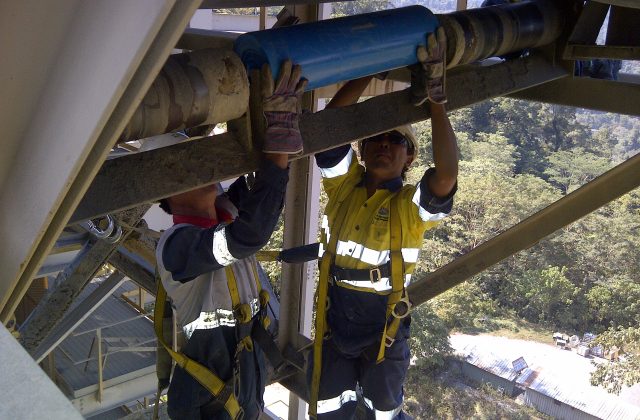

ULMA Conveyor Components, tailored mining solutions

At ULMA Conveyor Components we know that every case is unique. That is why we analyze the conditions and challenges facing conveyors and their components and offer optimized solutions for each case.

In addition, our PERFORMANCE product line, for optimum performance under normal conditions, and our ENDURANCE line, for maximum durability under extreme conditions, are developed with maximum system customization to ensure performance and durability.

ADDED VALUE OF ULMA ROLLERS AND COMPONENTS

Maximum durability

Our rollers offer the greatest durability on the market, with a 50% increase in service life. This does not just reduce the risk of unexpected shutdowns, it also extends maintenance intervals, improves security for operators and reduces both the inventory and annual supply costs.

01. Top-quality raw materials

In the first phase of the analysis, we make sure we understand the customer’s business: we identify their needs and their scale.

02. Quality control

We carry out rigorous controls on the receipt of raw materials, components and sub-processes.

03. Implementation

We implement a system of continuous supplier evaluation, improvement actions and training.

04. Lean Manufacturing

We operate according to Lean Manufacturing principles, with an optimal and dedicated layout design for each product line, which allows us to manufacture efficiently, repetitively, cost-effectively and on time.

05. Tailored manufacturing

We manufacture to exacting standards, ensuring a precise, tailored fit for your needs.

06. Controls

We carry out process controls in the factory using indicators and continuous improvement actions.

07. Laboratory testing

We carry out routine and specific tests to ensure quality.

08. Performance analysis

We analyze the performance of our products at customers’ premises, which provides us with valuable data to continuously improve our processes and consistently produce more durable products.